Automotive 2K Light Bar

USER FRIENDLY, SERVO ELECTRIC VALVE GATE (SEVG+) SYSTEM HELPS OPTIMIZE PROCESSING FOR FLAWLESS PART FINISH

A global OEM vehicle brand was looking to refresh the look of one of their full-size vehicles. The updated design included the use of a new rear light-bar. The PMMA light bar incorporated a 2-color design (clear red/gloss black). The gloss black material makes up the majority of the component. Since the part was quite long (59”) and required a high-quality finish, it was critical to ensure that the finished part quality requirements were met. The long length of the part and the sub-runner details increased the risk of quality defects appearing, such as knit lines.

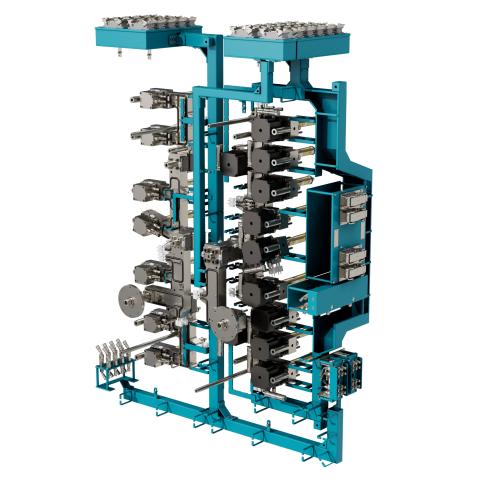

The production solution consisted of two Dura+ hot runner systems combined into one tool (one for clear red, the other for black). Dura+ hot runner systems are high-performance solutions optimized for automotive lighting applications. The production tool with the combined systems were operated on a rotary table as a 2K solution.

To prevent quality defects such as knit lines and blush from appearing on the part, the system for the black shot incorporated Mold-Masters Servo electric Valve Gate (SeVG+) actuation control system. The SeVG+ system allows for complete, precise control of each individual valve pins opening and closing profiles which make it much more technologically advanced than traditional actuation systems. SeVG+ gates were programmed to open sequentially in an acutely precise manner which allows the user to control the flow front of the resin as it fills the part to prevent part quality defects from appearing.

As a result, SeVG+ opened up the processing window for the molder enabling the parts to be produced to specification without any visual defects. In addition, one of the process technicians during trials reported that

“The Mold-Masters SevG+ actuation control system was much easier to use than other servo electric control systems that are commonly used in automotive applications.”

SeVG+ offers benefits outside of processing enhancements. These include compact servo motors that enables the mold-maker to maintain more steel to support the cavity side of the mold which helps minimize deflection. This helps prevent flash at the part edge and enhances long term durability of the mold. The proprietary direct drive design of the SeVG+ servos also help to eliminate any potential for play/delay that can occur with the linkage design of competitive systems.