Commodity Automotive Lighting Components

EcoONE-Series Lights the Way for Commodity Automotive Applications

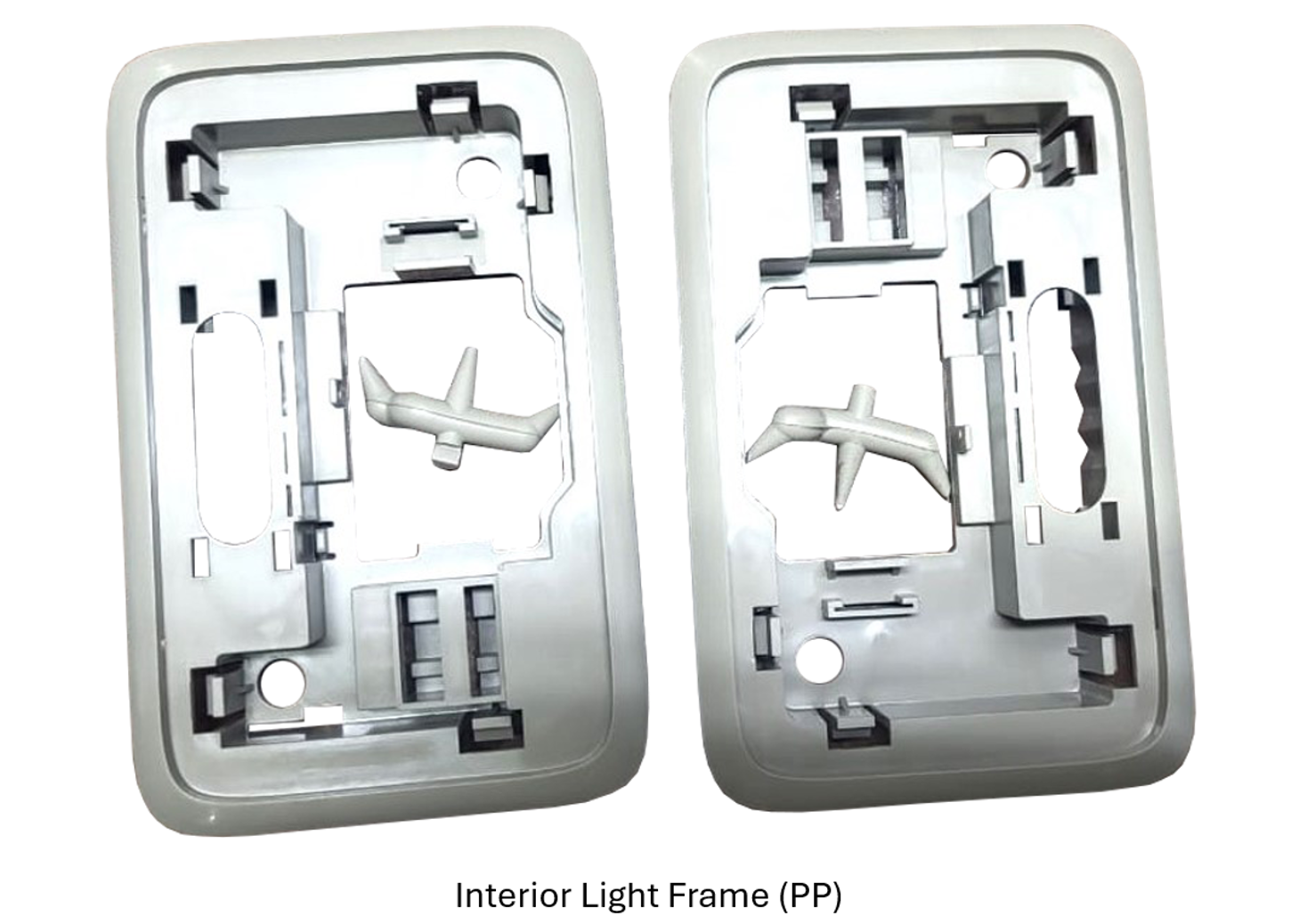

An automotive molder in India had two commodity light frame applications. An interior light frame molded from PP and a fog light from molded from PC. Both were currently being produced using cold runner systems. As these were being transitioned to high-volume production, the cold runner systems were no longer viable as the injection pressure was too high and there were quality issues with the existing production method (warpage, weld lines).

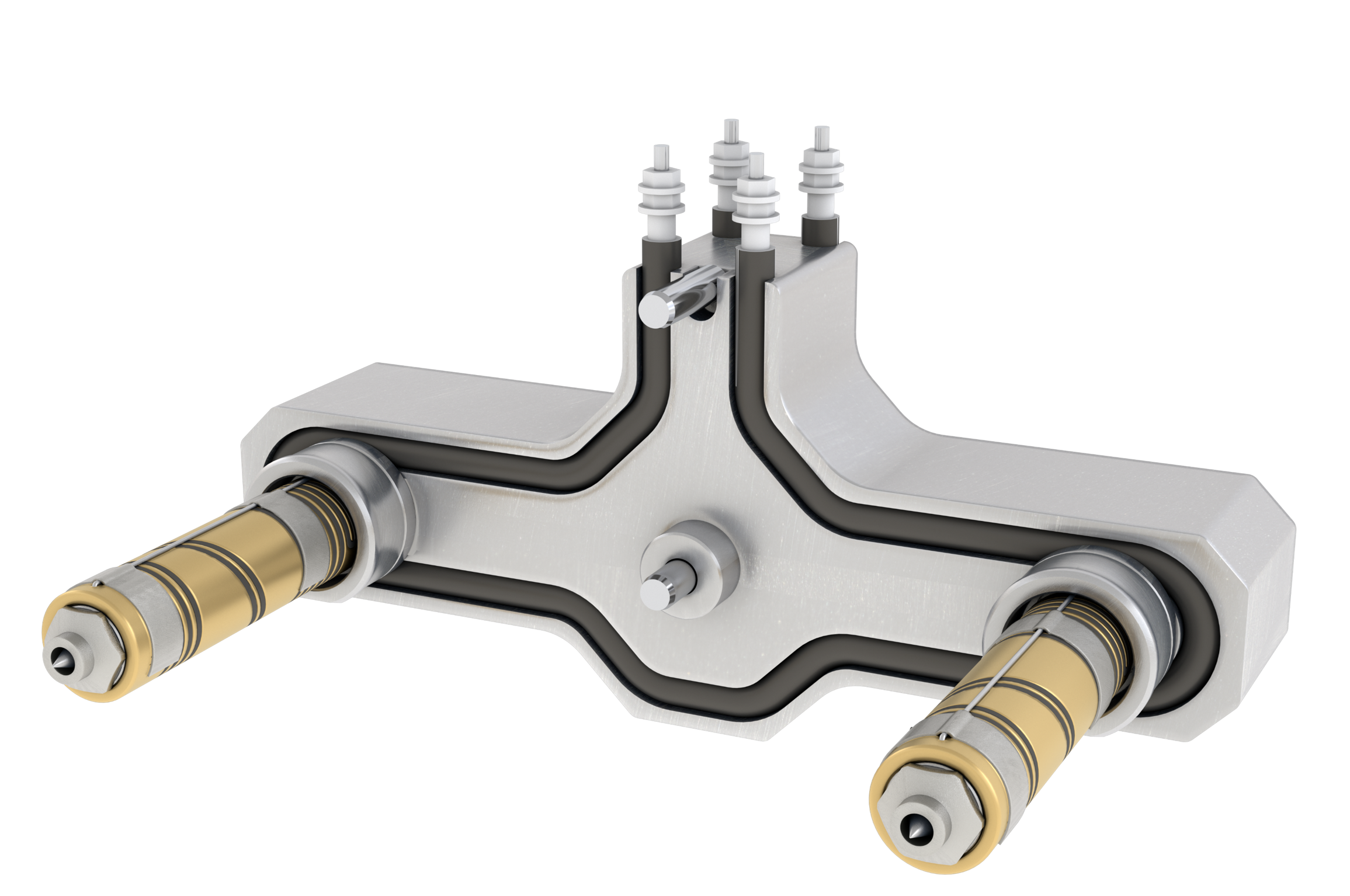

As these were commodity applications, the customer chose Mold-Masters EcoONE-Series 2-drop hot runner systems. Not only did the molded parts meet the required dimensions, but the part and gate quality was improved (eliminated warpage and weld line). In addition, the transition from cold runner to hot runner allowed the molder to lower cycle times by up to 27% (62s -> 45s) and minimize scrap. Ultimately the customer was very happy with the EcoONE-Series overall performance.