创新而独特包装应用以可承受的成本迅速进入市场,从而在竞争对手中脱颖而出,并重新定义了包装行业。常见的应用包括小型模内贴标容器、大桶、化妆品罐、一次性咖啡胶囊等等。

Requirements

Case Studies

多材料洗手液包装

迅速而经济地通过E-MULTI提高您的注塑容量以满足不断增长的需求。

Hagleitner卫生学国际股份有限公司成立于1971年,一直致力于创新的卫生解决方案。他们的产品种类繁多,从肥皂和消毒剂分配器到清洗和冲洗系统的配料系统,再到高效的清洁剂。这家家族公司自己生产所有产品。总部位于萨尔茨堡以南的泽尔阿姆西,集化工技术生产、纸张整理和塑料加工于一体。

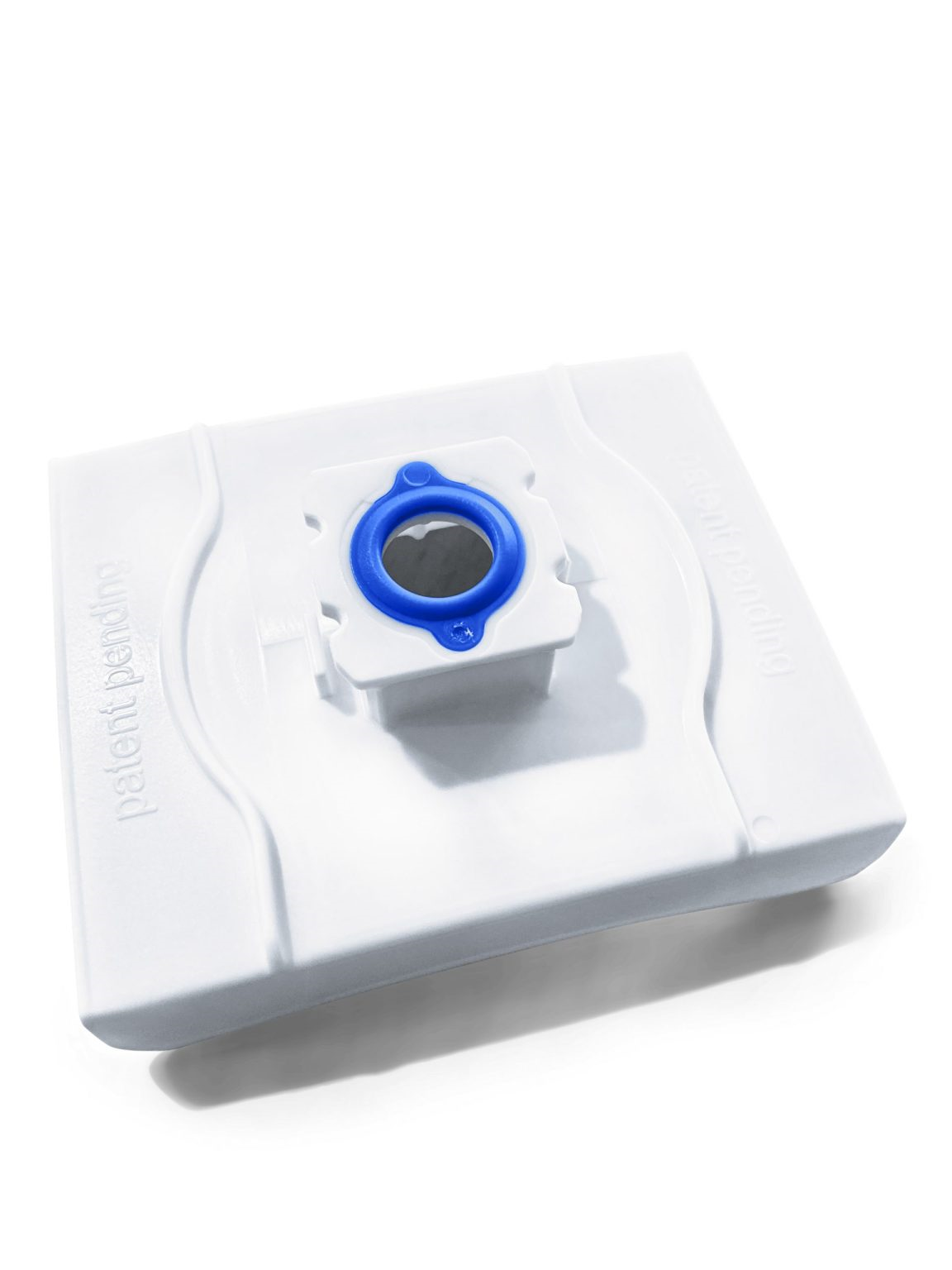

自从新冠疫情流行以来,洗手液一直是最受欢迎的产品之一。分液器不仅是医院和护理设施的标准,而且现在也在许多公共、零售和办公环境中。公司为员工和访客提供消毒剂,以帮助防止COVID-19的传播。为了能够快速、轻松地重新加注非接触式分液器,Hagleitner开发了重新填充“真空袋”。这些补充装每个都由一个管状袋和一个带有集成式封口的转接件组成。 倒置插入分液器后,封盖滑盖会自动打开。

自从新冠疫情流行以来,洗手液一直是最受欢迎的产品之一。分液器不仅是医院和护理设施的标准,而且现在也在许多公共、零售和办公环境中。公司为员工和访客提供消毒剂,以帮助防止COVID-19的传播。为了能够快速、轻松地重新加注非接触式分液器,Hagleitner开发了重新填充“真空袋”。这些补充装每个都由一个管状袋和一个带有集成式封口的转接件组成。 倒置插入分液器后,封盖滑盖会自动打开。

结合有集成密封件的转接件是在4 + 4转盘模具中使用两组分注射成型工艺生产的。首先,注入由白色聚丙烯制成的肩板,工具旋转后,将蓝色TPE密封件直接注入到零件上。在COVID-19之前,Hagleitner每天在一台机器上(20小时/ 5天)生产10,000个补充装。

为了满足激增的订单,这家奥地利卫生公司不得不在不到一周的时间里将产量翻了一番。仅仅增加现有成型设备的产量无法满足日益增长的需求,因此需要启动第二个成型设备。这种创纪录的实施速度部分是由Mold-Masters E-Multi辅助注塑装置实现的,该装置使他们能够将其现有的单一注塑机转换为可以进行多材料应用成型。 这两个成型设备的结合几乎在一夜之间将产量提高到每天15,000个单位(24小时/ 7天)。

Hagleitner的Hans-JürgenLandl表示,与Mold-Masters的合作非常出色,尤其是与奥地利当地代表的合作。 “这是真正的伙伴关系”。

Mold-Masters E-Multi辅助注塑装置是一个经过实践检验的有效平台,已在全球范围内使用,可轻松,经济地将任何注塑机转换升级,实现多材料注塑。它可以在水平、垂直或介于两者之间的任何位置安装。它还与多种热塑性和LSR材料兼容。由于采用电动方式,因此与液压替代品相比,它的工作范围要紧凑得多,其伺服电机可实现高精度、可重复性和可靠性的生产。它们还能够在整个生产设施中使用,或者相对容易地从一个地点运送到另一个地点。Hagleitner多年来已经在其现有注塑机上使用了多个E-Multi设备,因此他们已经熟悉了所有好处。尽管E-Multi的供货时间仅为5周(比新型注射机要快得多),但是当它们没有现货发售时,一周之内就能获得一台E-Multi本身就是一个挑战。

由于Hagleitner强大的合作伙伴网络,他们意识到他们的供应商(多年来一直为他们提供罐子和瓶子)在他们自己的工厂里有相同的E-Multi装置。供应商通力合作,把这台设备送过来进行改装。作为第二个单元的一部分,Hagleitner将他们的复制备份模具投入了全职生产。剩下的就是历史了。仅用几天时间,这两个成型单元就将产量提高到了每天15,000单位(24/7)。

有了E-Multi,比装第二个固定注塑单元更灵活,而且它还可以快速集成到任何其他注塑机中。 这方面的必要条件当然是具有相应接口的适当设备。 - Hans-Jürgen Landl, Hagleitner

这是如何利用Mold-Masters产品优势来实现其他人无法实现的任务的众多示例之一。 Mold-Masters感到自豪的是,我们的客户能够利用我们的产品作为其解决方案的一部分,以在全球范围内打击COVID-19。

如果您需要类似的解决方案,请立即联系Mold-Masters。 https://www.moldmasters.com/form/contact-us

复杂的纸盒用密封盖制造

E-Multi实现生产流程优化,最大化生产效率

“E-MULTI的精准射料量和可重复性是这一应用成功的关键组成部分。”

- Roberto Silla, President, EasyPlast (EU)

EasyPlast,一家总部位于欧洲的公司,自1994年以来一直致力于模具制造和注塑成型。该公司专注于为消费品制造多腔模具,并使用PP、LDPE、HDPE和LLDPE进行零件成型。可提供的零件包括盖子、胶囊、分配器、套管、医疗器具、家居用品、包装材料等。该公司每年生产超过十亿个成型零件,为国内和国际市场提供高质量的产品。

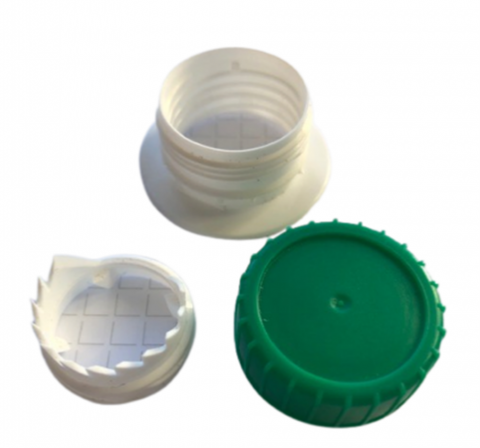

EasyPlast曾生产一种复杂的纸盒式密封盖(HDPE 3组分螺纹盖,双色)。当前的工艺是在3个独立

的模具中单独成型每个零件。该特殊的密封盖设计包括一个切割部件,当消费者打开密封盖时,它可以打开铝箔密封。

在该工艺中,单个零件通过机器人从模具中取出并送到一个装配夹具中,最终完成组装,并将组装完成的盖子完整地弹出。

EasyPlast希望改进生产工艺,以提高整体生产效率,降低零件成本,具体包括:

- 最大限度地减少设备利用率和人工成本

- 提高零件质量

- 减少循环时间(和处理时间)

- 节省占地空间

EasyPlast开发了一种特殊的24+24+24三层叠模,并获得了专利。作为解决方案的一部分,EasyPlast使用了E-Multi(EM4)辅助注塑单元和控制器来注塑具有第二种颜色的零件。

E-Multi安装在落地支架上,采用水平配置,几乎与压力机平行(15°角度)。E-Multi之所以被采用,是因为它具有精确的注塑能力、可重复性、可靠性和射料量。

根据客户估计,这一新系统可以将注塑和组装过程的完成时间减少约50%。在组装后,三个零件的收缩均匀,收获了极高的公差和出色的零件质量。通过在成型后最小化处理需求,报废率降低高达75%(从2%降至0.5-1%)。根据客户报告,这一新工艺使得零件成本降低了约40%,并预计每年至少能节省10万欧元。客户将这些降本归因于更为高效的工艺(得益于E-Multi和特殊模具设计)。这套工艺减少了1名工人和2台注塑设备,所需的冷却设备更少、缩短生产时间和组装时间,降低了废料率和能源消耗。

此外,由于该处理并非生产过程的瓶颈,故E-Multi尚未在应用中发挥它的性能极限,EasyPlast希望在未来进一步改善循环时间。其控制器也因其界面友好、易于使用和安装而备受青睐。

客户对该单元非常满意,因为它的工作非常出色。他们计划为未来(类似的)项目订购另一个单元。

如果您需要类似的应用,请随时与Mold-Masters联系: https://www.moldmasters.com/form/contact-us