PRESS RELEASE

Mold-Masters® Introduces Dura®+ Optimization Enhancements That Improves Overall Productivity by Minimizing Downtime and Enhancing Overall Performance.

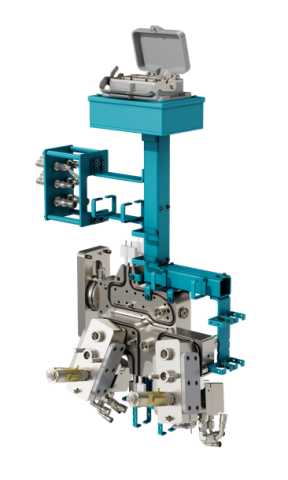

Mold-Masters®, a leading developer and supplier of hot runners, controllers, auxiliary injection and co-injection systems, has announced a series of enhancements to its Dura®+ hot runner systems. These improvements are designed to streamline installation, reduce downtime and elevate overall system performance.

Mold-Masters Dura+ hot runner systems are the clear choice for automotive lens applications delivering consistent, high-quality production of automotive lens components that demand exceptional clarity. Engineered for today’s most challenging resins - including PC, PC-ABS & PMMA. Dura+ systems are available with either Brazed nozzles (fixed heaters) or F-Style nozzles (field replaceable heaters). Dura+ systems are also available with our industry-leading 10-year warranty.

The Dura+ system’s enhancements include:

- Installation at Room Temperature (F-Style Nozzles)

- Reduced Nozzle Bore Cut-Outs (F-Style Nozzles)

- Compound Nozzles (F-Style Nozzles)

- Compact Quick Release Actuators

- Quick Valve Pin Stroke and Height Adjustment

- Waterless Actuators featuring PACT

Installation at Room Temperature

Dura+ systems utilizing F-style nozzles that are delivered drop-in ready (pre-plumbed/pre-wired) are now engineered to be installed and uninstalled at room temperature. It can be pulled directly from the shipping box and placed into the mold. This helps to significantly reduce installation time, eliminate extra equipment such as a temperature controller and improve safety conditions during installation, assembly, and removal.

Compact Nozzle Bore-Cut Outs and Compound Nozzles

Dura+ (F) nozzles are available in customizable lengths up to 1,000mm and feature more compact nozzle bore cut-outs. These nozzles incorporate field replaceable heater bands and gate seals to ensure molders can respond and fix issues quickly on-site to minimize downtime. Most gate seals are interchangeable between the older and newer nozzle designs, so customers can convert to the new system, in many cases, without any special retooling.

Compound Dura+ (F) nozzles are also available, which feature a tapered nozzle body to maintain gate access in areas with limited clearance. These nozzles feature a larger runner channel at the base of the nozzle to reduce pressure drop and improve melt flow performance. Compound nozzles are a durable one-piece design without any split line connection in transition and are available in standard lengths up to 1,000mm.

Compact Quick Release Actuators

Dura+ actuators now have a more compact height and cut-out than previous actuator designs. It also features a quick release feature that allows it to be detached from the hot runner system, without having to remove the valve pin with it, to make servicing the actuator much quicker and easier.

For comparison, hot runner system designs that need to pull the valve pin to remove the actuator require that the system be heated to release the valve pin from the cold resin which takes extra time to complete. In addition, on systems incorporating long valve pin lengths, it would be necessary for hydraulic lines to be fully disconnected which adds to service times and risks creating a mess from leaks when having to disconnect the hydraulic lines. This extra complexity and hassle are eliminated with the new quick release design.

Quick Valve Pin Stroke and Height Adjustment

In addition to offering more compact actuator dimensions, all units now offer quick and easy adjustment of valve pin height and stroke as standard. The valve pin height can be adjusted without the need to remove the actuator from the mold. This enhancement makes adjustments during the system installation process much quicker and easier without the need for machining.

Waterless Actuators

Waterless actuators feature an advanced design incorporating PACT (Passive Actuator Cooling Technology) which maintains operating temperature by transferring heat to the top clamp plate.

As such, they can eliminate conventional hose-plumbed cooling circuits to actuators. Benefits to the molder include faster mold changes (less components to manage, allows for simultaneous shut down of Mold Cooling and Hot Runner), provides long-term performance reliability (eliminates issues associated with clogged cooling circuits) and enhances safety when the hot runner is used at Pre-Heat stations. Valve pin height adjustment is also a standard feature.

Dura+ hot runner systems are fully compatible with the Mold-Masters advanced Servo Electric Valve Gate (SeVG+) actuation control system. SeVG+ delivers precision control over each valve pin’s actuation profile – ideal for the most challenging applications.

To learn more about Mold-Masters products and innovations or to speak with a technical expert, please visit www.moldmasters.com or contact info@moldmasters.com.