Mold-Masters Co-injection hot runner systems (formerly Kortec) utilizes industry leading technology to convert mono-layer components to multi-layer while maintaining your existing part quality and productivity levels. The core layer can be either a high performance barrier to improve part performance or a post consumer recycled (PCR) resin to lower part costs. Ideal for a wide range of packaging, medical, consumer goods and automotive applications.

Features

Co-Injection Nozzles

- "3-Layer" Flow.

- Core on "zero" gradient of velocity profile.

- Total control of core distribution.

- Shot-to-shot and cavity-to-cavity consistency.

- Pneumatic Valve Pin Actuation.

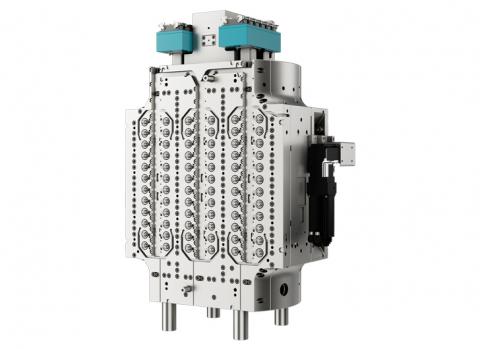

Co-Injection Manifolds

- Optimized hot runner channels.

- Low residual volume.

- Improved shear balance (verified in production).

- Cavity-to-cavity uniformity.

- Leverages Mold-Masters technology.

Standard Mold Construction

- Standard cooling.

- Standard cavity spacing.

- Ability to retrofit existing molds.

High Compatibility

- Ability to utilize existing tooling.

- Use with monolayer and multilayer tooling.

Specifications

- Applications are reviewed on a case by case basis. Please contact co-injection@moldmasters.com for more information.