INDUSTRY LEADING LSR PROCESSING CAPABILITIES FROM KIPE MOLDS

Now get valve gated cold decks for precision Liquid Silicone Rubber (LSR) molding from Mold-Masters through our strategic partnership with KIPE MOLDS. KIPE brings over 40 years of highly successful LSR knowledge and experience to our customers. Your best solution for optimized processing of LSR in single shot or over molding applications across any industry.

Features

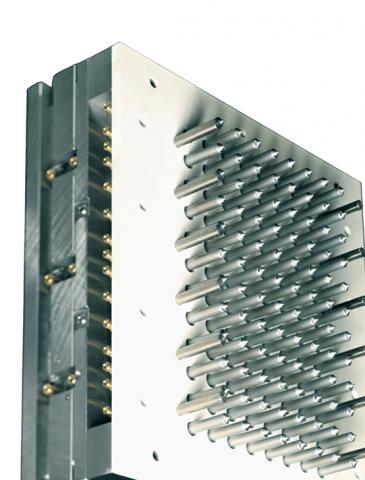

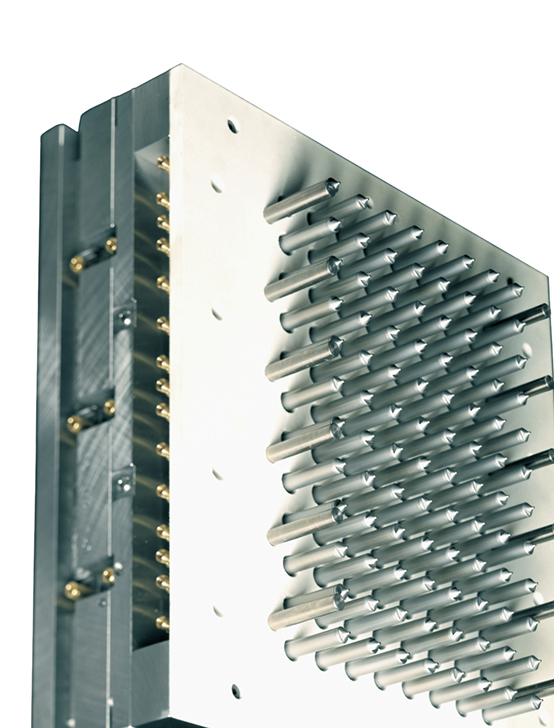

Specialized LSR Nozzles

- Wide shot range.

- Tight pitch design.

- Optimized gate design for faster cycle times and exceptional part quality.

Integrated Water Jacket

- Accurately maintains process temperatures.

- Helps ensure highest molded part quality.

Valve Gated Designs

- Exceptional process control.

- Wider range of material viscosity compatibility.

- Long term maintenance cost savings.

Valve Gate Flow Control

- Regulate flow to enhance fill balance.

- Simply turn a dial to adjust opening stroke.

Global Network Support

- Expertise in a variety of LSR applications.

- Local spare parts and service support.

- Consultations available.

Specifications

- Drop Range: 1 – 128

- Shot Range: 0.005g – 150g

- Nozzle Lengths (Std): 70, 90mm (2.24", 18.90")

- Minimum Pitch: 38mm (0.75")

- Advanced Molding Capabilities: Micro Molding, High Cavitation, Tight Pitch, Inside Gating, Multi-Material.

- Actuation Options: Pneumatic only

Available Gating Styles

Valved

- Tapered

- Cylindrical

Actuation Options

Standard

- Pneumatic Cylinder

Advanced

- Flow Control

- SVG (Sequential Valve Gate)

- Synchro Plate