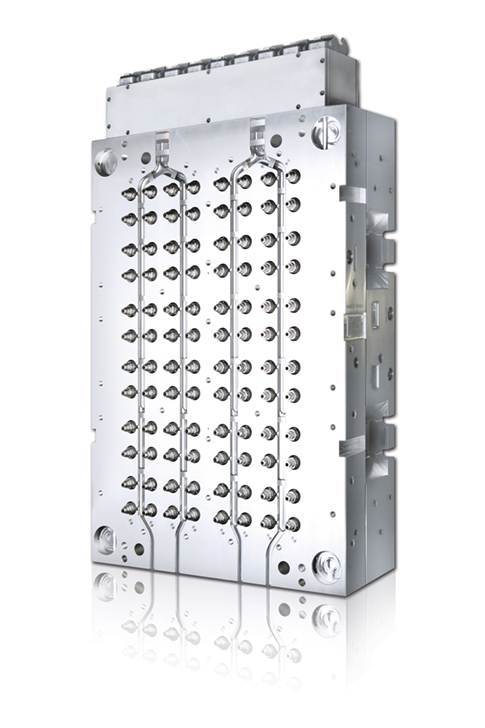

LIGHTNING FAST, SPECIALIZED CAP & CLOSURE SYSTEM

Sprint hot runner systems are specifically engineered for caps and closure applications. Optimized for reliable high speed molding, Sprint systems are capable of <2 second cycle times, fast color changes and low energy consumption. A range of special features ensures highest production quality while minimizing downtime. Now includes MasterSHIELD Technology as standard for enhanced leakage protection.

Features

Sprint Nozzles

- Excellent thermal profile (10% Max Variation*).

- Enhanced process repeatability.

- Produces high quality parts and minimizes scrap.

- NEW MasterSHIELD Technology for enhanced leak protection.

Hot Tip Thermal Gate Seal

- Optimized for high-speed molding.

- Excellent gate quality.

- High durability extends service life.

- 1 Year (3M cycle) warranty

- Industry standard gate cut-out and bubble.

iFLOW Manifold Technology

- Best in-class melt management.

- Industry leading mold fill balance.

- Rapid color change performance.

- Extensive flexibility for design optimization.

- Patented melt flow geometry, flow path options and runner shapes.

- Reduced stack height.

Brazed Heater Technology

- Superior thermal balance.

- Enhances rheological balance.

- Exceptional reliability minimizes downtime.

- Eliminate spare heater costs.

Industry’s Best Warranty

- Available 10 year coverage.

Specifications

- Shot Range: <1g – 10g

- Runner Ø: 8mm (0.31")

- Nozzle Length Range: 87 - 127mm (3.43" – 5.00")

- Minimum Pitch: 47mm (1.85")

- Bore Cut-Out Ø: 32mm (1.26")

- Advanced Molding Capabilities: High Cavitation, Tight Pitch.

- Available as a hot half system only.

Available Gating Styles

Non-Valved

- Sprint Standard Tip

- Sprint Color Change Tip