Mold-Masters recognizes the importance Bio-Resins represent in helping to preserve the environment for future generations. We have invested considerable time and money in understanding these cutting-edge materials to ensure we’re ready when you are. Trust in Mold-Masters to drive positive results on your next Bio-Resin application. Contact us at Bio-Resins@moldmasters.com

Overview

Understanding Bio-Resins

Bio-Resins can be very challenging to process compared to the common resins they typically aim to replace. This of course can make producing good parts very difficult and sometimes impossible.

Important Considerations

Obviously, many Bio-Resin grades differ from one to the other. Some can be easier to process than others, but it is common for many to have narrow process windows due to Thermal or Shear sensitivities.

Additionally, if the Hot Runner design is not optimized for Bio-Resins, this can also be a source or even compound the issue. Therefore, taking into consideration Flow Pattern, eliminating hang-up spots and other design requirements are also critical elements that need to be considered.

Typical Processing Challenges

When molding with Bio-Resins, a wide range of visual defects can appear based on the processing characteristics of the material and the hot runner configuration used. These defects include:

- Jetting

- Streaking

- Splay

- Flow Marks

- Knit Lines

- Burn Marks

- Stringing

Extensive Testing and Experience

Mold-Masters has spent extensive time testing a wide selection of these materials in our R&D facility and through our partnership with the University of Massachusetts. In addition, we worked with leading converters and brand owners to select resins and to define a priority test sequence. This research has as allowed us to evaluate and understand their unique properties and effective processing requirements. Most importantly, Mold-Masters has a variety of real-world Bio-Resin application experience which includes high cavitation production tools that have been in long term production.

Critical Knowledge Database

Mold-Masters Bio-Resin application success is directly related to our experience and our ability to pull information from our invaluable Applications Library. This data directs our team to select the correct product line(s) and assists us in designing the most optimum solution given the material at hand.

Read about Mold-Masters success

ETMM Mold-Masters Bio-Resin Cover Story.pdf

Technical Advantages

#1 IN PROVEN PROESSING SOLUTIONS

Mold-Masters hot runners, controllers, co-injection and auxiliary equipment have been successfully used to process a range of Bio-Resin applications.

Mold-Masters systems incorporate specialized technology that is well suited to overcome the processing challenges associated with Bio-Resins that help ensure application success including shear and temperature sensitive characteristics.

Best In-Class Melt Management

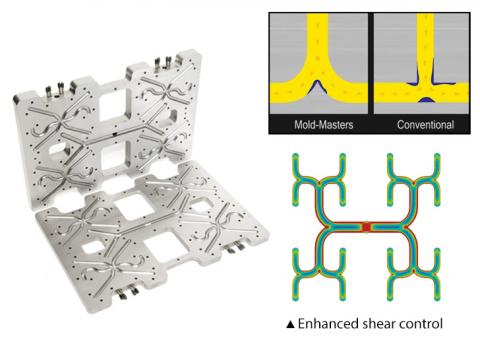

- A result of Mold-Masters iFLOW Manifold Technology.

- Superior management of melt characteristics including shear, temperature, pressure drop and more.

- Endless design options and flexibility for optimization.

- Industry leading mold balance.

- Rapid color change performance.

- Reduced stack height.

Superior Thermal Management

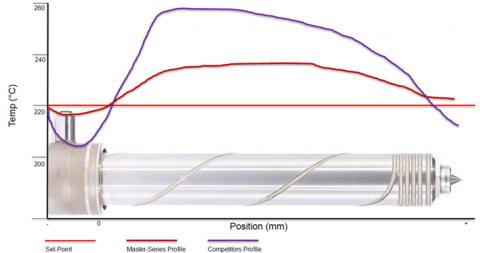

- A result of Mold-Masters Brazed Heater Technology.

- Especially valuable for Bio-Resins with shear or temperature sensitivities.

- Superior thermal profile precision.

- Thermal balance across the whole system.

- Significantly improves part quality and reduces scrap.

Precise Temperature Control

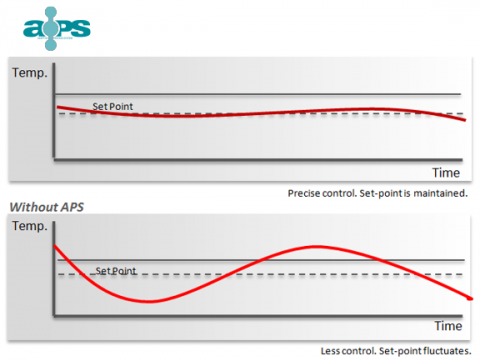

- A result of Mold-Masters TempMaster APS Control Technology.

- Proprietary Auto-Tuning Algorithm.

- Automatically adapts to process variables of each zone.

- Control accuracy of 1°F (0.5°C) minimizes variability.

- Optimizes the performance of any hot runner system.

Advanced Applications

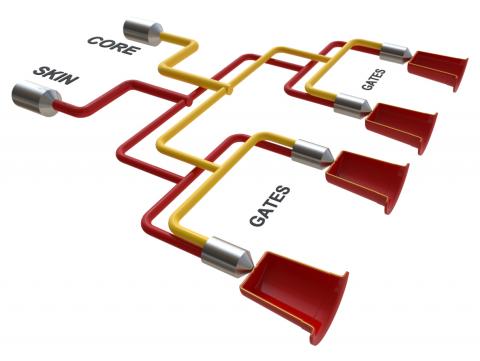

- Includes Mold-Masters Co-injection Technology

- Incorporates high performance barriers that extends shelf life by up to 5x, lowers production costs and offers greater design flexibility.

- Co-injection is compatible with many applications including packaging

- Conversions and full turnkey solutions available.

Downloads

Case Studies

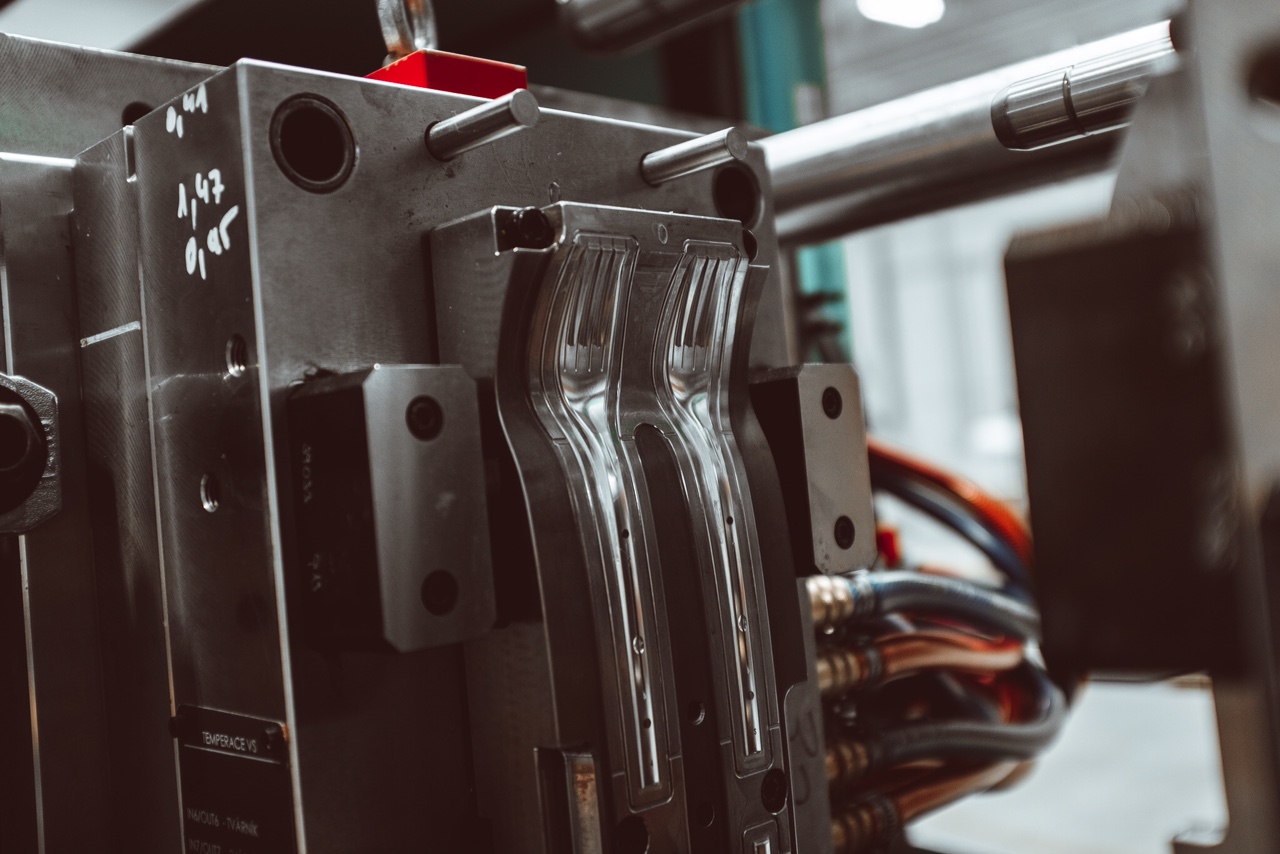

BIO-RESIN SINGLE-USE UTENSILS

FOR US, MOLD-MASTERS IS MORE THAN A SUPPLIER, THEY ARE A DEVELOPMENT PARTNER

- Josef Žádník, CEO, Refork

Utilizing a proprietary Bio-Resin blend, the company Refork, utilizes injection molds to produce sustainable single use utensils. The Bio-Resin material consists of Wood Flour (primary material sourced as waste from the wood industry), PHA (binder) and various renewable minerals (to enhance mechanical properties). This special blend is fully biodegradable in home compost, soil or marine environments. Refork utensils include a selection of forks, knives and spoons. www.refork.com

Refork developed their proprietary blend that would be suitable for injection molding by involving Mold-Masters at an early stage. That process involved testing various biopolymers (PLA, PBAT, PHA’s) which would act as the binder. There were several key variables that needed to be achieved for the end product to be a success. This included:

- High biodegradability criteria

- have good mechanical properties,

- be acceptable for food contact,

- offer good processability,

- be visually appealing (color/texture),

- be suitable for mass production,

- higher HDT (Heat Deflection Temperature) point.

There were 3 key challenges during the injection molding process that Refork needed Mold-Masters to overcome:

- Prevent material degradation (The bio-resin material tended to degrade quickly during the injection process as a result of the biopolymer binders and wood flour).

- Achieve a consistent cycle time that could be scaled to mass production.

- Minimize the injection pressure to allow s

ystem compatibility on a smaller machine.

ystem compatibility on a smaller machine.

Mold-Masters supplied several optimized Master-Series hot runner systems (hot halves) depending on the production capacity that was required for each product. This included 48 and 24 drop production hot halves and a 4-drop hot half for R&D testing. Mold-Masters TempMaster M2+ hot runner temperature controllers were also utilized to maintain tight process control.

Mold-Masters worked closely with Refork to supply hot runner solutions that allowed them to successfully achieve all of their goals. Not only was Refork able to process their unique material, but Mold-Masters hot runners were able to achieve a consistent cycle time, minimize scrap and decrease the required injection pressure by 500 bars to allow the molds to be operated with smaller machines. Mold-Masters hot runners are currently used by Refork to produce over 12M Bio-Resin utensils on a monthly basis (151M annually).

If you have a sustainable Bio-Resin or PCR application contact us for an application review today.