PRECISION CONTROL FOR SERVO DRIVEN AUTOMATED MOLD FUNCTIONS

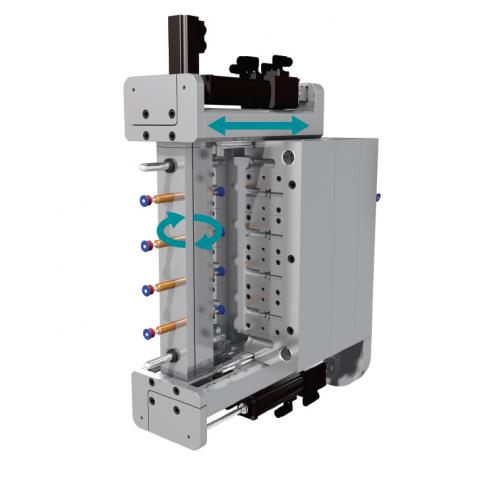

Molding environments are increasingly being digitized. Servos for mold functions offer superior precision, control and repeatability over traditional methods. The M-Ax servo axis motion controller offers the greatest process control accuracy and easiest adjustments of automated linear and rotary mold functions.

Features

Precise Servo Control

- Control a wide variety of mold functions.

- Each M-Ax servo can be easily switched between liner or rotary axis movements.

- Integrated hot runner temperature control available.

Single, Large Touch Screen HMI

- Simple and intuitive to use.

- Centralized control of servo and temperature control.

Fully Configurable

- Maximum flexibility.

- Programmable user defined I/O.

- Integrate additional molding functions.

All Electric Operation

- Viable for clean room applications.

- Reduces energy consumption by up to 60%.

Servo Functions Include:

- Valve gates

- Core pulls

- Coining plates

- Index plates

- Stripper plates

- Ejector plates

- Rotary tables

- Spin stack

- E-Drive Synchro Plate

- E-Multi Auxiliary Injection

Specifications

- Movements: Rotary or Linear

- Number of Drives (Max): 3*

- Servo Amps: 4.5 - 44*

- Programmable I/O (Std.): 16 (8/8)

- Programmable I/O (Max): 64 (32/32)

- IMM Interface: E67

- Mains Voltage: 3 AC 200-480V

- Motor Supply with Controller: Yes (customer specified)

- Available with Integrated Temperature Control: Yes

*Custom configurations available upon request.