A brand you can trust

SINCE 1963

History

1963

Founded by Jobst and Waltraud Gellert in Toronto, Canada. Mold-Masters would become the first company to exclusively manufacture hot runners.

1965

New technology revolutionizes temperature uniformity for unmatched part quality.

1970

New comprehensive family of hot runners advances plastic part manufacturing.

1980

Fused metal composite delivers even greater temperature control and uniformity.

1984

Mold-Masters expands into the Asian market with new facility in Kawasaki, Japan.

1985

Mold-Masters supports its controller business by opening a new manufacturing facility.

1989

Mold-Masters expands into Europe with its manufacturing facility in Baden-Baden, Germany.

1991

Global program initiated to educate and empower plastic professionals.

1993

A new strategic sales office to support growth throughout South East Asia.

1993

First global hot runner manufacturer to receive ISO certification.

1995

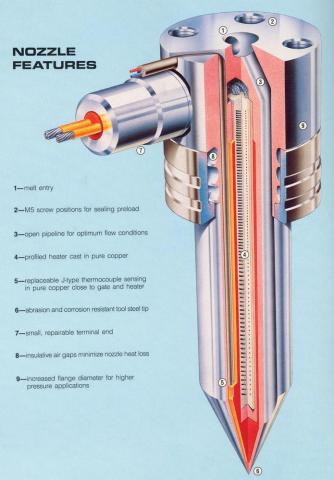

Nickel fused heaters and application engineered tips make temperature control more precise than ever.

1998

Prodevco established exclusively for Research, Development and Testing.

2000

Mold-Masters expands its global footprint into LATAM.

2003

Years of manufacturing innovation results in the new benchmark in hot runner technology.

2005

Full manufacturing and sales facility opens in Kunshan, China.

2005

Precision valve pin alignment technology is introduced to prevent wear and maintain gate quality for millions of cycles.

2006

Mold-Masters Europa expands manufacturing facility by 25% to meet growing market demands.

2006

Mold-Masters expands into India by opening a Sales and Engineering office.

2006

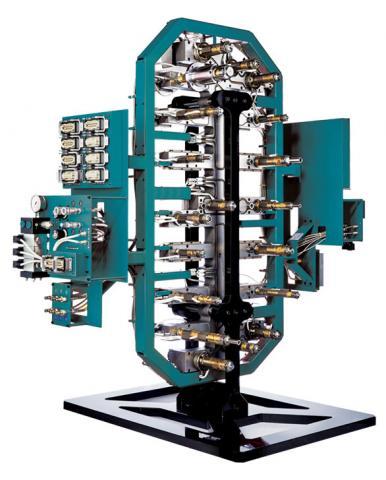

Our first generation of pre-assembled, pre-wired and tested hot runner systems designed to drop-in, connect and inject.

2008

Mold-Masters strengthens its global support network by opening a new strategic North American service center.

2009

Mold-Masters supports its European growth by opening new regional sales offices.

2010

Mold-Masters expands its global manufacturing footprint.

2010

Mold-Masters introduces its auxiliary injection unit. Easily and economically convert any injection machine to allow for multishot capabilities.

2013

Our second generation of drop-in systems. Now more robust than before for larger applications.

2014

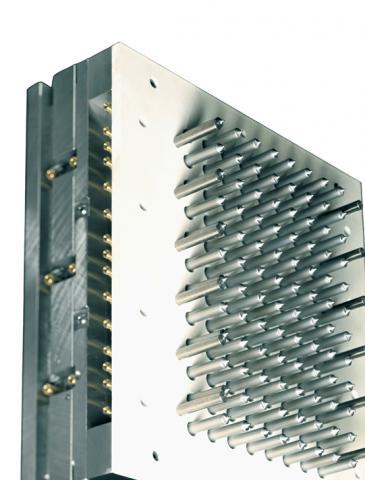

Mold-Masters strengthens its multi-layer co-injection business to become the industry leader.

2017

Our most advanced hot runner system to date, designed to process the most challenging modern resins.

2017

The latest generation of hot runner system for molding automotive lenses with absolute clarity.

2017

Mold-Masters supports the digitalization of molds by introducing a precision servo axis motion controller.

2018

Mold-Masters lowers the barrier to entry of LSR (Liquid Silicone Rubber) applications for our customers by introducing a new LSR Auxiliary Injection Unit.

2018

Our flagship temperature controller is upgraded with a range of advanced enhancements.

2018

Mold-Masters further supports our customers LSR (Liquid Silicone Rubber) molding requirements through a strategic partnership with KIPE MOLDS.

2019

Mold-Masters introduces a revolutionary new controller technology that eliminates conventional TC cables (50% of all mold cables). Available only on TempMaster M3 temperature controllers.

2019

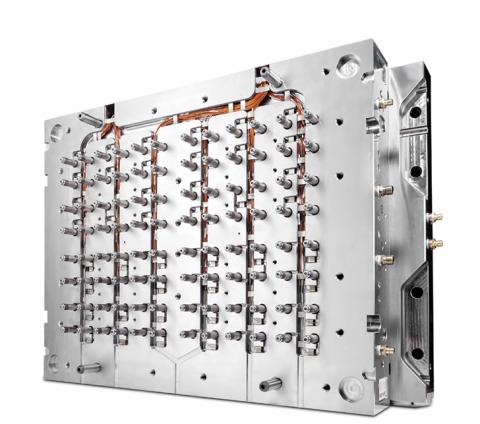

Mold-Masters introduces its new hot runner system for high pressure, thin wall packaging applications.

2019

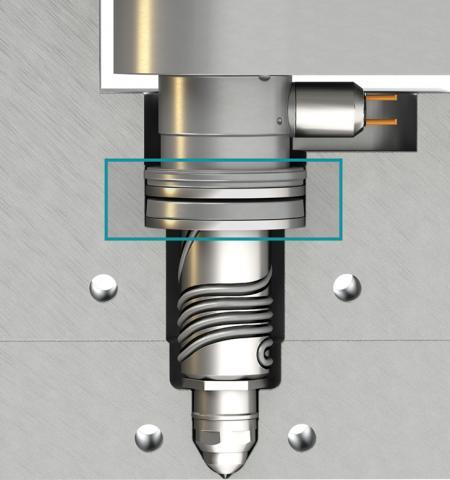

The next evolution in advanced in-line side gate designs. Offers enhanced performance while significantly reducing maintenance times.

2019

Mold-Masters introduces Passive Actuator Cooling Technology (PACT) to eliminate traditional cooling lines.

2019

Servo Electric Valve Gate. Our most advanced actuation control system for the most challenging applications.

2019

Mold-Masters introduces an advanced patent pending design that offers enhanced leakage protection.