Economical high volume production, flawless quality, high volume production, hard-to-mold polymers and tight deadlines are the challenges in the automotive industry as it looks to create lighter weight parts to improve fuel economy while supporting Just-in-Time (JIT) delivery requirements. Common applications include automotive exterior, automotive interior, under hood components and automotive lenses (lighting).

Requirements

- Medium to large part production

- Part weight range from 500g to 5,000g+ (typical)

- Repeatability

- Class "A" surface finishes

- High clarity (automotive lighting)

- Ability to process challenging resins

- Tight gate access

- Multi-material molding

- Fast delivery/service

- Minimal downtime

- Repeatable production

- Sustainability (PCR)

Common Resins

MM Solutions

- Drop-in systems

- Nozzle lengths up to 1m

- Compact nozzle bore dimensions

- Rapid color change performance

- Angled manifold designs

- Lens specific solution

- Advanced servo actuation process control systems

- Rapid delivery

- Field replaceable components

- Global support network

- 24hr spare part delivery

- Auxiliary injection units

- Co-injection multi-layer PCR technology

Case Studies

Front Headlight Lens

SEVG+ (Servo electric Valve Gate) ALLOWS FOR RAPID PROCESSING OPTIMIZATION ON TIER 1 LIGHTING APPLICATION

Mold-Masters customer, a Tier 1 automotive lighting component manufacturer, was contracted to produce the front lighting components of an exciting new electric SUV for a major North American brand. As electric vehicles no longer require air flow to enter an engine bay, this new PC lighting component stretches across the entire front grill .

For the automotive brand, it was critical that this component be produced without any visible flow lines on the lens. A mold-flow analysis determined that the application required sequential filling in order to achieve the necessary results. However, the component manufacturer traditionally used pneumatic actuators which do not provide the repeatability or accuracy required to achieve consistent processing for such an application.

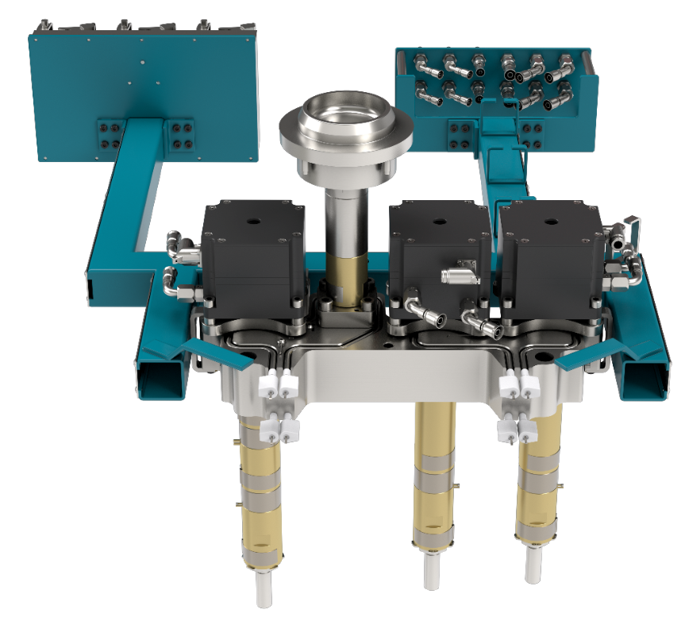

Mold-Masters hot runner solution for this application was a Fusion-Series G2 system (F7000 nozzles, extended hot valves) and incorporated our advanced SeVG+ (Servo electric Valve Gate) actuation control system. The SeVG+ system was favored by the customer because of its simple and compact design in addition to Mold-Masters sales and engineering support. SeVG+ features a direct drive design unlike competitive systems that incorporate levers, gear boxes and other components. This not only reduces spare part requirements but also minimizes cut-out requirements. Additionally, the height of our new 2nd generation motor has been reduced by 48% which minimizes stack height. The height of this motor is now only 90mm high.

and incorporated our advanced SeVG+ (Servo electric Valve Gate) actuation control system. The SeVG+ system was favored by the customer because of its simple and compact design in addition to Mold-Masters sales and engineering support. SeVG+ features a direct drive design unlike competitive systems that incorporate levers, gear boxes and other components. This not only reduces spare part requirements but also minimizes cut-out requirements. Additionally, the height of our new 2nd generation motor has been reduced by 48% which minimizes stack height. The height of this motor is now only 90mm high.

In this specific application, each nozzle/gate of the hot runner system fed a sub-runner that fed into the left and right-side lighting component. There were 3 sub-runners total.

Initially, the 2 outboard drops (Gates 1&3) produced splay. To eliminate this issue, the Mold-Masters team worked through stepping the profile on these drops. The pin was opened slowly for the first 50% of the stroke and then opened quickly for the rest of the movement. Profiling the individual drops allowed for this issue to be quickly resolved in under 10 shots.

Had this hot runner system not been fitted with the SeVG+ system, fixing the splay would have involved adjusting the process at the injection press which would influence all gates including the center gate which was good. It is clear that the flexibility of the SeVG+ system to precisely control individual gates on challenging applications allows for processing solutions to be quick and easy.

2K Side Mirror

E-MULTI DELIVERS STABLE PROCESSING, MINIMAL SCRAP RATE AND RAPID ROI

“I am fully convinced that this is the best auxiliary injection unit for our processing requirements that is currently available on the market.”

Mold-Masters customer designs and manufactures automotive rear-view mirrors for brands such as Fiat, Alfa Romeo, Lancia, Iveco, VW, Ford, Skoda, BMW and more. This specific application involved the production of a new 2K automotive side-mirror using a competitor’s hydraulic auxiliary injection unit.

The process on this 2K automotive component could not be stabilized over several months which resulted in a variety of part defects which included burrs and short shots. The scrap rate was about 14%. The goal was to return to economical production by optimizing the process and updating equipment. In addition, the machine downtime was also significantly higher compared to similar cells. This was a result of the special maintenance requirements of the competitor’s auxiliary injection unit they were using at the time.

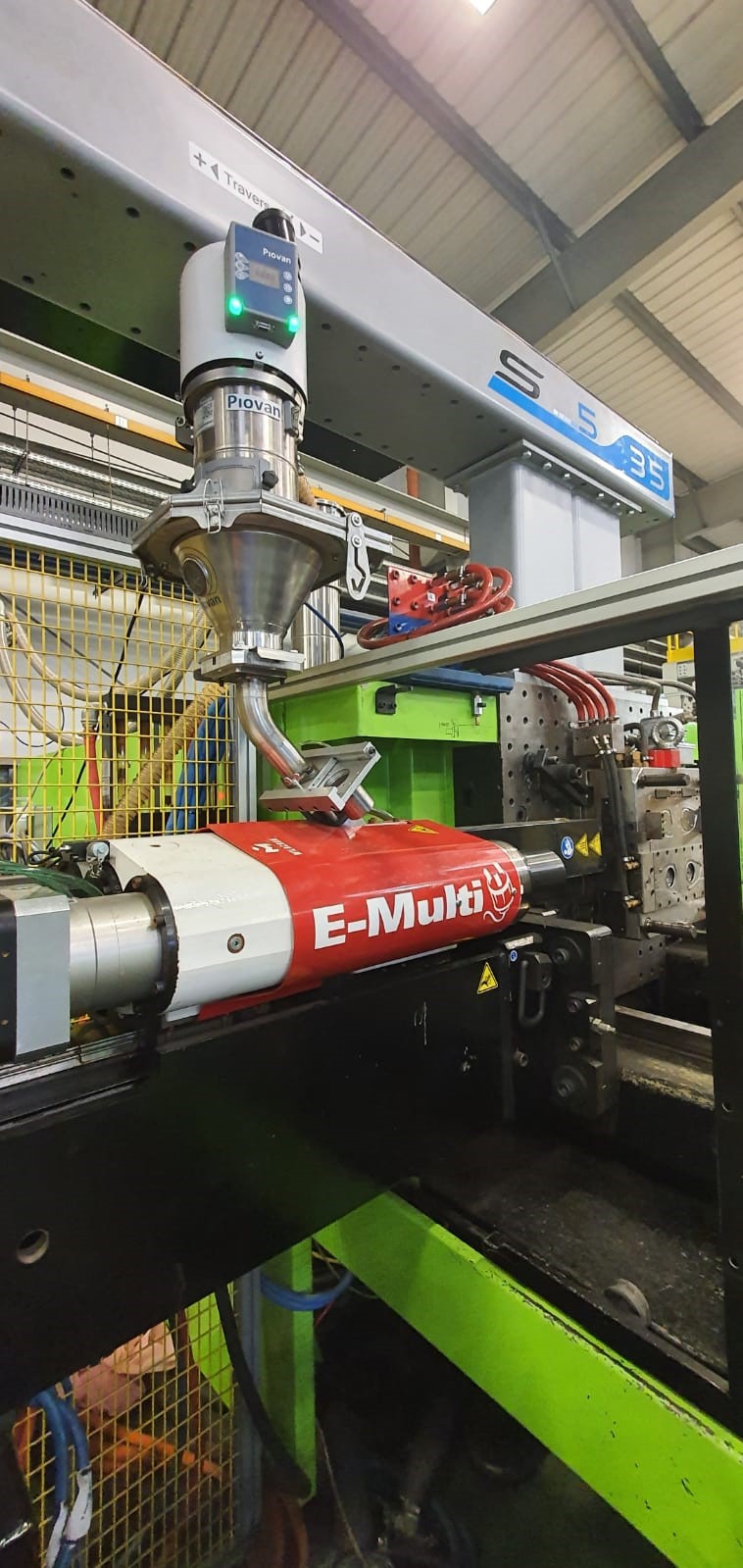

The Mold-Masters E-Multi auxiliary injection unit (EM3-100-28) was selected to replace the poorly performing competitor auxiliary injection unit.

The E-Multi was installed on the existing injection machine in a horizontal configuration and offers additional features that are not available with their current competitive unit (ex: program up to 10 injection profiles with holding pressures). The E-Multi’s comprehensive overview with statistical process data and overall production tracking gave new insights to further improve parameters that were not accessible with the previous system.

Although systems integration was not a priority when the cell was put together, the advantage of the E-Multi control system acting as the brain for overall process management and eliminating excess equipment to save valuable space on their shop floor was a huge benefit. The E-Multi controls the auxiliary injection molding process and incorporates temperature control and other various smart control features to fully integrate into a single control device.

After the E-Multi was installed and the process optimized, the scrap rate with E-Multi was minimized to less than 1%. This has resulted in cost savings of 15.000 EUR in less than 4 months which allowed the system to be amortized in less than 2 years (the system is planned to be in production for 6+ years). Downtime was also significantly reduced with E-Multi thanks to its minimal maintenance requirements.

Our customer realized that purchasing the cheapest unit from competitors was not always the best for their business where performance and quality are critical to their business. E-Multi proved the value of investing in a system with a far lower total cost of ownership pays for itself quickly. E-multi can also save a lot of hassle for the engineering and shop floor team.

Li-Ion Battery Cover

SUMMIT-SERIES INCREASES UPTIME BY 400%+ IN CHALLENGING PFA BATTERY APPLICATION

A new customer approached us about molding Li-ion battery covers to meet the growing demand from the electric car industry from a challenging PFA resin. This special resin is important to this application as it’s resistant to corrosion from the battery fluid and it prevents the battery from overcharging. Traditionally, components made from this material have been produced using cold runners. However, as the material is very expensive, the customer was hoping to transition to hot runners in order to lower their scrap and production costs.

The demands of molding with a PFA resin makes it a challenge for any injection molder. The major issue with this resin is that during the heating process the material releases a fluorine gas that is corrosive to steel. Both hot runner system and injection molding machine are affected by this gas. Once the corrosion starts it spreads rapidly and leads to valve pin seizure and eventual leakage. Before approaching Mold-Masters the customer had tried working with several other hot runner suppliers who all failed. Their systems would only operate for a week and then require extensive repairs and cleanup maintenance. This was not a sustainable practice, so the customer continued their search for a better solution.

This fantastic opportunity involved Mold-Masters collaborating closely with the customer in order to ensure their application was successful. Mold-Masters Summit-Series hot runner system is specially suited to such applications as it is intended to accommodate challenging resins that are corrosive/abrasive or have temperature/shear sensitivities. Summit-Series incorporates a variety of special materials and coatings into its components that protect the system from harmful corrosive materials in order to extend service intervals.

By utilizing Mold-Masters Summit-Series hot runners uptime was increased by at least 400% compared to the competition (1 month vs. 1 week). If the mold remained in continuous production, some Summit-Series systems have been able to remain in production for up to 12 weeks (1 million cycles) significantly extending the time between service intervals and unscheduled downtime. This customer was very pleased with the results and now relies on Summit-Series hot runner systems for this application.

The Mold-Masters Summit-Series hot runner system offers a clear competitive advantage for PFA applications. This success will surely transition more manufacturers to Summit-Series on PFA applications that ultimately pays for itself through increased uptime and reduced scrap.