Balance scales

Thin Wall Butter Container

Mold-Masters Co-injection Technology Supports Customers Sustainability Initiative in Thin Wall Packaging By Incorporating Recycled Flake Materials

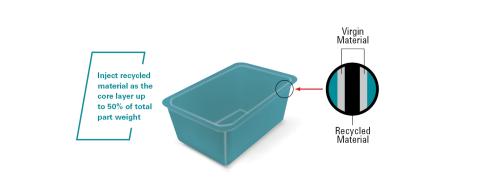

Mold-Masters is dedicated to offering solutions that support our customers sustainability efforts. When it comes to sustainable applications, Mold-Masters industry-leading co-injection multi-layer technology, offers the ability to combine two separate resins into a single 3-layer melt flow. This enables our customers to inject high Flake/PCR content in the core layer up to 50% of total part weight. Mold-Masters has demonstrated how its Co-injection equipment can be used by molders to minimize cost per part (save on virgin material) and help our customers meet their sustainability targets.

Our customer is an international provider of packaging, components, and insulation solutions. The company’s commitment to sustainability is integrated throughout the value chain, from production of raw materials and end goods, to recycling of used products. With a vision to protect people and goods for a better every day, they are leading the change towards a circular economy.

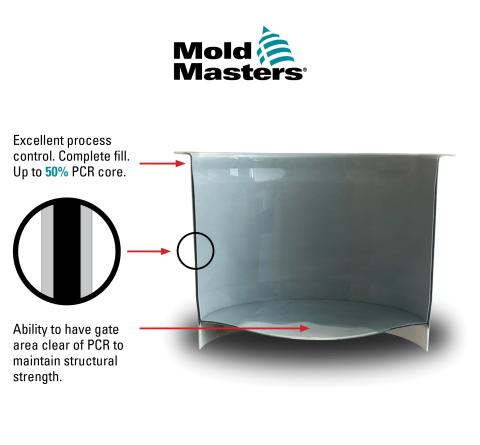

With these sustainability goals in mind, they have leveraged Mold-Masters Co-injection technology to deliver more sustainable thin wall packaging products to the marketplace. Our customer successfully tested a thin wall rectangular shaped butter container and achieved up to 40% recycled material (flakes) into the core layer. Mold-Masters Co-injection system was able to exhibit amazing results with a wide range of recycled flake material with Melt Flow Rates (MFR) ranging from 12 to 100. Not only were they able to process such a range of materials, but they were able to achieve stable processing and shot-to-shot repeatability without any penalty to cycle time (compared to the original mono-layer process). This successful trial opens the door to full scale high-volume production capabilities.

Mold-Masters Co-injection Technology has come a long way. Today, the technology has advanced to include compatibility with a wide range of containers and products with weights as low as 5g up to 950g (5 gal/20 L pails). Increasing recycled content enables our customers to maximize sustainability targets and implementation ROI on their application. Our precise process control allows Mold-Masters to achieve more consistent and fuller core fill. Recycled material is fully encapsulated in virgin resin which prevents contact with container contents such as food. One of the major advantages of Mold-Masters Co-injection technology is that there is typically no penalty to cycle time or part quality, and in many cases, molders can reuse their existing tooling (minor modification may be required).

Mold-Masters makes implementing this into your application simple and economical with our Co-injection CONNECT package. This package includes an E-Multi auxiliary injection unit which allows our customer to convert any injection molding machine to co-injection. The package also includes the co-injection hot half, process control, engineering, and start-up support.