NEWS RELEASE

Mold-Masters is proud to announce that our industry-leading co-injection multi-layer systems are now available for injecting light blocking barrier materials as the core layer for Thin Wall Packaging applications. Light blocking barriers reduce light transmittance by up to 99.9% to extend product shelf life and preserve freshness and flavor of dairy products.

LIGHT BLOCKING BARRIERS FOR THINWALL PACKAGING

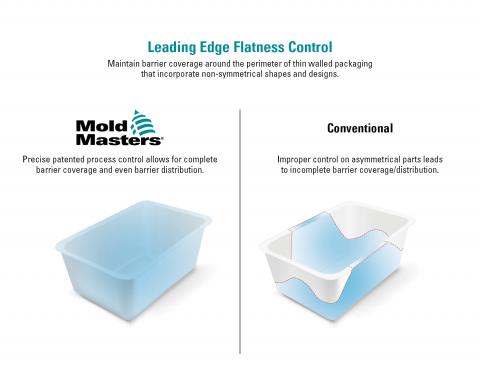

Mold-Masters currently offers co-injection hot halves for thin wall packaging in any cavitation. The light barrier can be virgin or recycled material, both are compatible. Dosing of Black Core can be customized to meet the specific requirements of the molded part (Dosing 5% to 30% dependent on total part weight). Mold-Masters patented process control capabilities allows us to maintain complete core barrier coverage around the perimeter of non-symmetrical shapes and designs without core breakthrough.

Additionally, Mold-Masters Patented Co-injection Process for thin wall offers excellent heat seal bond (uniform thickness for good adhesion), a fully encapsulated barrier, dimensional stability, design freedom and is compatible with IML (In Mold Labelling). In many cases, the existing cold half can be reused. A co-injection hot half only replaces the mono-layer hot half.

LOWER CAPEX AND MINIMIZE RISK FOR THIN WALL PACKAGING CO-INJECTION APPLICATIONS (Co-injection CONNECT)

With Mold-Masters Co-injection Connect Package, molders can easily and economically convert their existing single shot injection molding equipment over to produce co-injected (multi-layer) parts. By converting existing equipment this allows molders to reduce their CAPEX of injection equipment (E-Multi vs. 2k Injection Machine) which also helps minimize project risk. Additionally, a Co-injection solution with E-Multi can be implemented with much faster lead times compared to purchasing a completely new 2k IMM. Mold-Masters Co-injection technology is compatible with a wide range of materials including Bio-Resins and PCR.

INDUSTRY-LEADING CO-INJECTION TECHNOLOGY

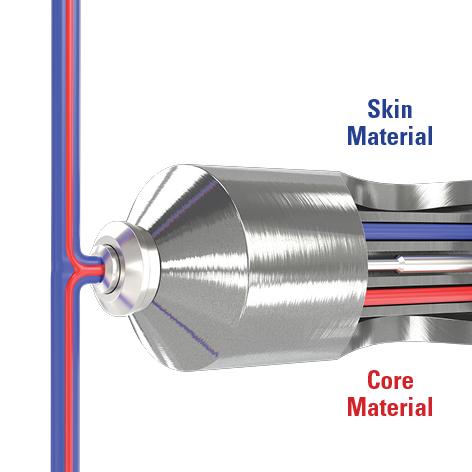

Mold-Masters industry-leading Co-injection Technology utilizes a proprietary nozzle design that allows for two different resins to be combined into a single 3-layer melt stream. By incorporating a high-performance barrier as the core layer in packaging products, co-injection extends shelf life, maintaining freshness and flavour, longer than mono-layer blends. From a processing perspective, Co-injection increases productivity by eliminating the requirement for secondary processes and minimizing scrap. It can also minimize the use of expensive mono-layer barrier materials. Mold-Masters Co-injection Technology is fully customizable to create a moisture, gas or light barrier for containers of all shapes and sizes without any penalty to a molders existing cycle time.

About Mold-Masters

Mold-Masters is a leading global supplier of hot runners, controllers, auxiliary injection and co-injection systems. We design, manufacture, distribute, sell and service highly engineered and customized plastic processing equipment that caters to every market. Mold-Masters is credited for patenting the first commercially viable hot runner system in 1965. Today, Mold-Masters conducts business in over 100 countries and employs a diverse workforce that exceeds 2,150 professionals. Mold-Masters Global Headquarters is located in Georgetown, ON Canada.

Media Relations

Miki Bogar – Sr. Manager, Global Marketing

905-877-0185 ext. 721

MBogar@moldmasters.com