2K AUTOMOTIVE FRONT BUMPER COMPONENT

E-MULTI AUXILIARY INJECTION UNIT ALLOWS MOLDER TO WIN NEW 2K PROJECTS BY EXTENDING PRODUCT PORTFOLIO

As a system partner, WELP Group (based in Germany) produces top-quality plastic components such as high-quality technical components, housing components and visible components (interior and exterior elements) which can be finished on their paint line, completely assembled, and delivered ready-for-installation (if required). Their range of machines includes more than 50 modern injection-moulding machines with locking forces ranging from 25 to 3,200 tonnes and 1C, 2C + hybrid, gas-assisted injection moulding, hybrid and insert / outsert technology. Many of their plastic injection moulding production operations take the form of fully automated assembly processes combined with optional high-precision hand-crafted work (where necessary). WELP Group supports the automotive, medical, and other industries with their capabilities, which ranges from engineering up to and including the finished component. The co-operation with Mold Masters existed with the subsidiary Farmingtons Automotive GmbH (a division of WELP Group) since 2000. During this time, we have successfully worked together on many complex projects. Farmingtons Automotive

Not only was a solution required to produce this front bumper, but as a supplier to the automotive industry, flexibility is critical to be able to quickly react to changing customer requirements. Farmingtons Automotive understood that this was not going to be their last 2K application. It became a priority for them to select an auxiliary injection unit that was flexible and easy to use so that almost all of their future 2K mold projects could be realized with their existing 1K injection molding machines and hot runner systems from multiple brands.

“IN OUR OPINION, THE E-MULTI OFFERS UNBEATABLE FLEXIBILITY.”

- Eugen Gaus, Head of Business Unit Tool Making, WELP Group, Subsidiary: Farmingtons Automotive GmbH (DE)

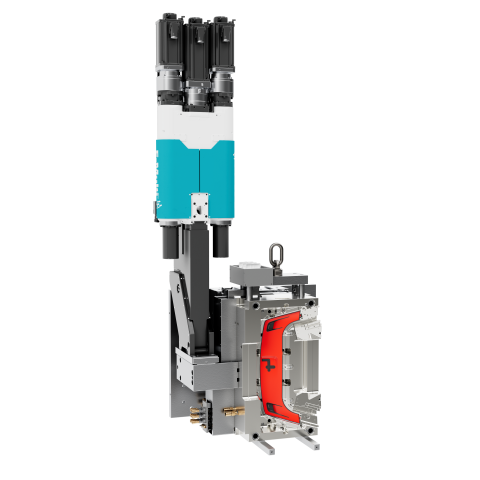

Farmingtons installed the E-Multi unit in a special vertical layout inside of the injection machine because of space restrictions on the non-operator side. The injection machine is positioned directly next to a wall. Mold-Masters, in co-operation with Farmingtons, created a special U-shaped link between the E-Multi injection unit and Mold-Masters Fusion Series G2 hot runner to accommodate the second shot.

In addition to improving cycle time and producing high-quality parts, the E-Multi has allowed them to win new 2K projects by extending their product portfolio. “In our opinion, the E-Multi series is unbeatable in terms of flexibility” states Farmingtons. Two major factors that were favored by Farmingtons was the E-Multi’s ability to inject high shot weights and the ability to utilize different screws depending on the application. Farmingtons states that “product quality and reliable, repeatable processing is critical to us”. Farmingtons confirms that Mold-Masters consistently delivers on these criteria and that their experience has been very positive throughout.

“PRODUCT QUALITY AND RELIABLE PROCESSING IS CRITICAL TO OUR BUSINESS. MOLD-MASTERS CONSISTENTLY DELIVERS BOTH.”

- Farmingtons Automotive GmbH (DE)